This is our original product and the most popular. Outstanding test results in the field (See EPA's ETV program – verified technologies) have shown this product to be capable of stand-alone water quality treatment on many sites and in most jurisdictions. For critical sites or jurisdictions with highly restrictive requirements, this machine is an effective pre-treatment system that controls trash, debris, accidental spills, and will remove 89% of all solids that reach the device. We know this because we service what we sell, and have the experience of over 5,000 maintenance operations to back up our test results with real field experience. From high density hot spots, to pre-treatment for sensitive land based LID applications, this is the machine of choice. The CrystalClean separator can treat water quality flows from 0.4 to 7.2 cfs, and stay on line for maximum flows of 2 to 36 cfs over the range of models. Check out our section on arrays for more possibilities if your flows are above 36 cfs. If you know what you need or are unsure of the proper product to use, fill out our Design Information Form on-line here and our registered professional engineers will get right back to you.

Here is a sample list of installations across the country….. Partial Installation List

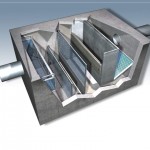

The CrystalStream Water Quality Vault

U.S. Pat. No. 6,797,161

How it works:- The fundamental principle applied is that things less dense than water float and things more dense than water sink.

- The device has a standing pool at all times.

- A reservoir spans the device from side to side and nearly to the bottom blocking flow from going directly to the outlet.

- Incoming storm water flows through a fine mesh in the trash basket, capturing floating debris and vegetative matter.

- Holding debris above the permanent pool prevents it from eventually becoming water-logged, sinking, and decomposing.

- The water proceeds around baffles slowing and spreading the flow and ensuring that the oil gathers at the top.

- As the water level rises, the oil flows over the edge of the reservoir and the water flows under it to the outflow pipe.

- More importantly, the reservoir provides 300 to 900 gallons of emergency spill protection.

- As the water rises out of the unit in the back chamber it passes through a 3/4 inch coconut fiber filter, designed to remove smaller floating or suspended materials.

- Other elements, such as absorbents, flocculants, or charcoal canisters, can be added to target specific pollutants.

- Maintenance is performed on an as-needed basis (usually twice yearly) through access points on top of the device.

- Floating debris is removed from the trash basket.

- Sediment is pumped from the bottom of the device.

- Oil is pumped out of the storage reservoir.